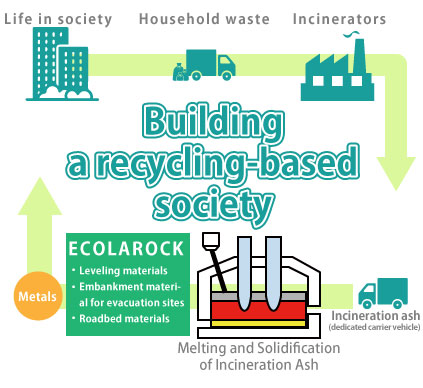

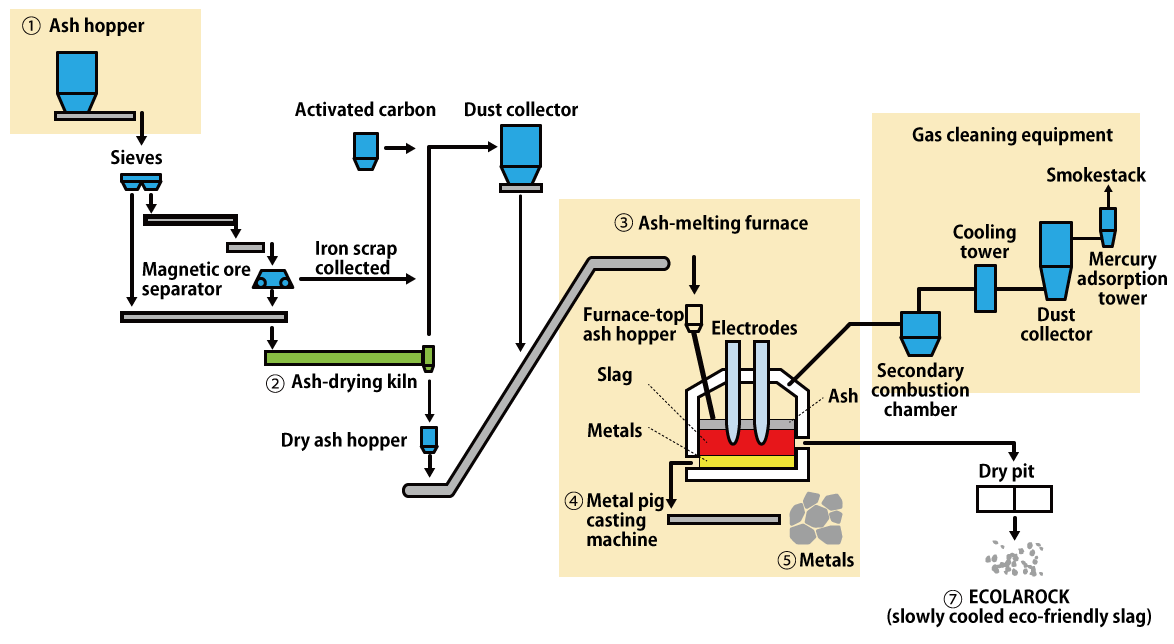

Melting and Solidification, Detoxification Treatment / Recycling

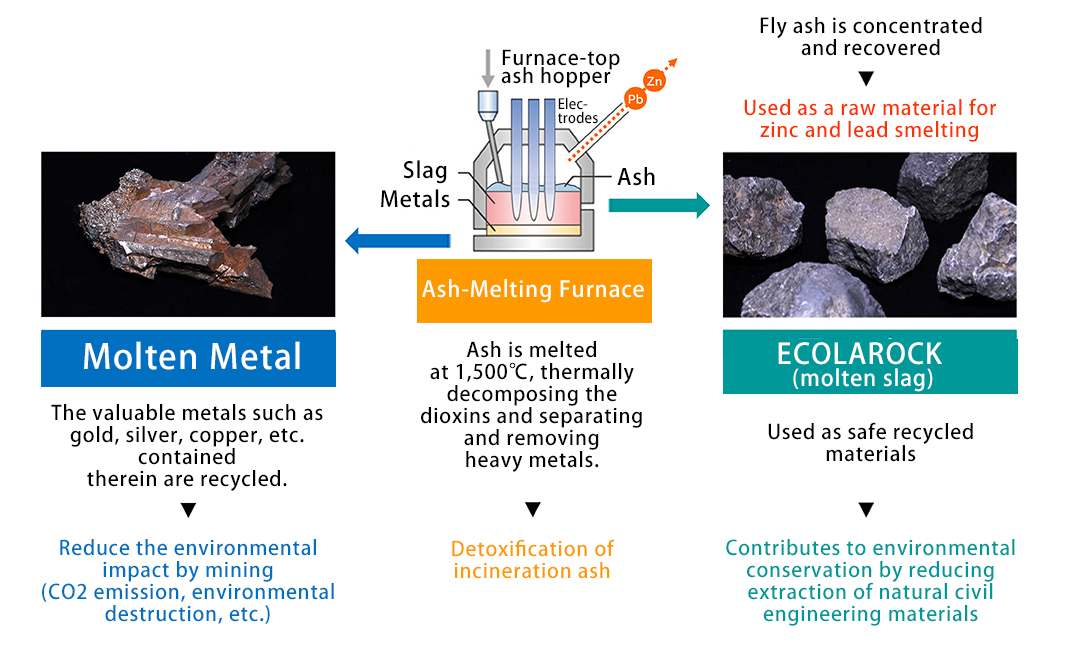

Much of the incineration ash generated nationwide has been disposed of in landfills. However, incineration ash contains dioxin and other toxic substances, and valuable metals such as gold and silver that can be reused are also disposed of. Furthermore, it is becoming increasingly difficult to secure additional landfill sites.

Features

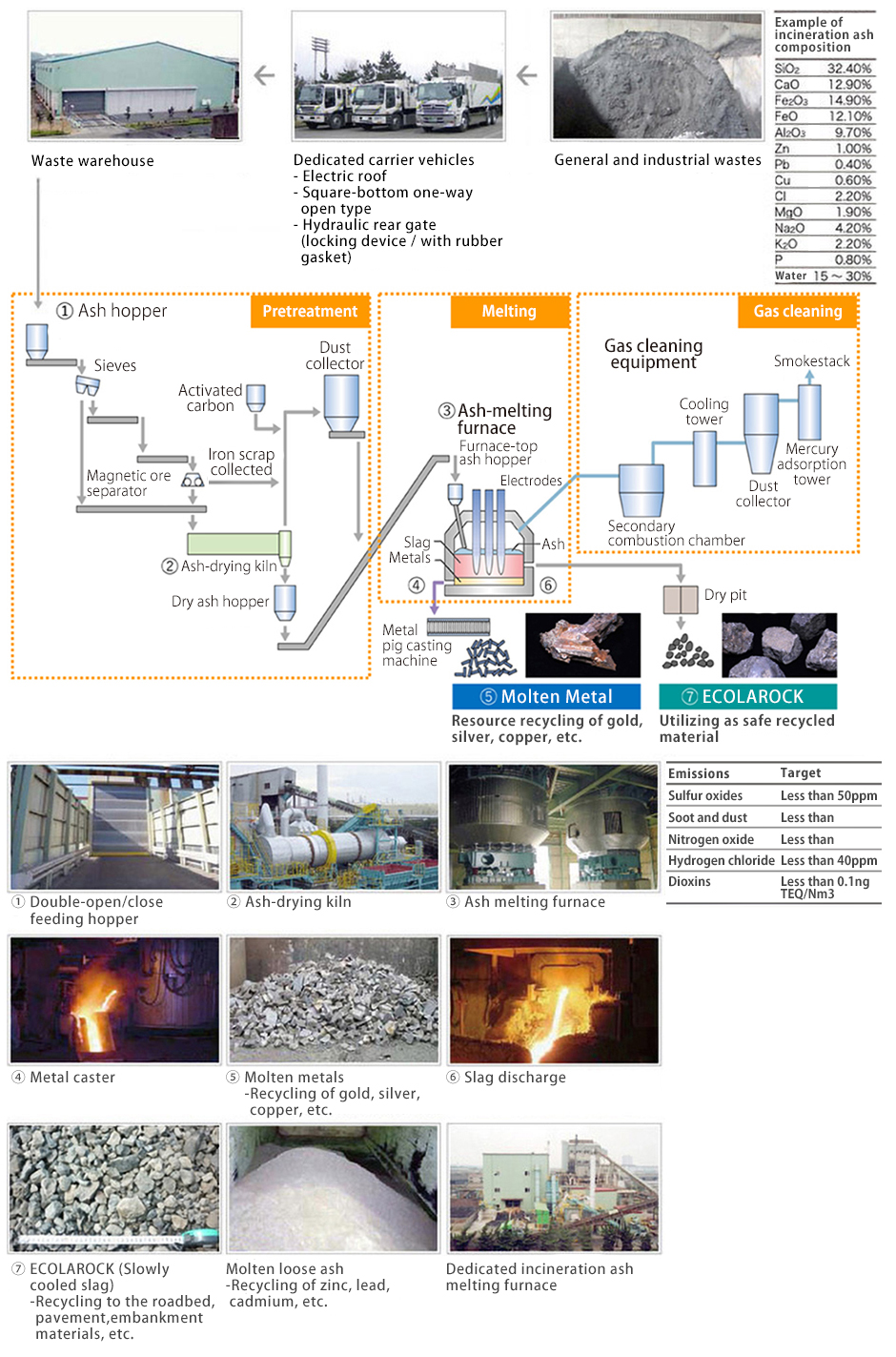

- Melting and solidifying waste at high temperatures breaks down dioxins and detoxifies and stabilizes heavy metals.

- The slag generated in the melting process (ECOLAROCK) is a safe, environmentally friendly product that can be recycled as building and civil engineering materials (e.g. roadbed materials, materials for river embankment work).

- Gold, silver, copper, and other valuable metals in the molten metal are recycled (urban mines).

One of the Largest Melting and Solidification Treatment Capacities in Japan.

Against this backdrop, in 1995 we became the first private company to start a business of melting and solidifying, detoxifying, and recycling incineration ash from general waste, and in 2002 we began processing industrial waste as well.

With the No.2 incineration ash melting furnace in 2004, the No.3 in 2018, and the No.4 in 2022, we now have four dedicated electric furnaces with a processing capacity of more than 130,000 tons per year, one of the largest in Japan. With our advanced technology and abundant experience, we are able to meet a wide range of needs from local communities and companies, and deliver safety and reliability.

*ISO14001 and ISO9001 certified

Features of Our Melting and Solidification

1. Melting by dedicated furnaces

Multiple treatment furnaces are in operation for 24-hour treatment, allowing customers to schedule their treatment plans with assurance.

2. Detoxification and stabilization of hazardous materials by high-temperature treatment

Melting and solidification is one of the methods used to dispose of soot and dust, which is a specially controlled waste designated by the former Ministry of Health and Welfare (Public Notice No. 194). Melting at high temperatures can completely detoxify dioxin.

3. Highly efficient volume and weight reduction

Volume is reduced to 35% and weight to 60%.

4. Resources recycling

After adjusting and uniformly melting incineration ash of various properties, we produce an ECOLAROCK with stable properties through gradual cooling. ECOLAROCK is highly evaluated as a civil engineering material such as roadbed material and leveling materials. In addition, gold, silver, and other valuable metals contained in incineration ash are recovered as metal and recycled.

*ECOLAROCK is a safe material equivalent to “JIS5032 Molten slag for roads made by melting and solidifying general waste, sewage sludge, or their incineration ashes”.

Target Waste

The following is a list of target wastes that we can treat.

1. General waste

Incineration ash, soot and dust, crushing residue, noncombustible residue, incineration residue of human waste, sludge

2. Industrial waste

Debris, glass and ceramic scraps, metal scraps, sludge (limited to inorganic sludge), mineral scraps, cinders, soot and dust

3. Specially controlled industrial waste

Sludge (limited to inorganic sludge), mineral scraps, cinders, soot and dust, etc.

4. Contaminated soil

Class II specified hazardous substances (excluding mercury and its compounds)

Class III specified hazardous substances (excluding polychlorinated biphenyls)

5. Other

Soil containing DXN (dioxins), excavation of landfill sites

Waste Melting and Solidification Processing Capacity

The following is a list of target wastes that we can treat.

1. Processing facilities

Dedicated electric furnaces (4 units)

2. Treatment facility permitted capacity (T/D)

520.0

![close[]](/en/shared/img/sp/closeBtn.png)