Digital Transformation

DX Vision

Realizing optimal manufacturing and creation of new value

through digital transformation and self-innovation

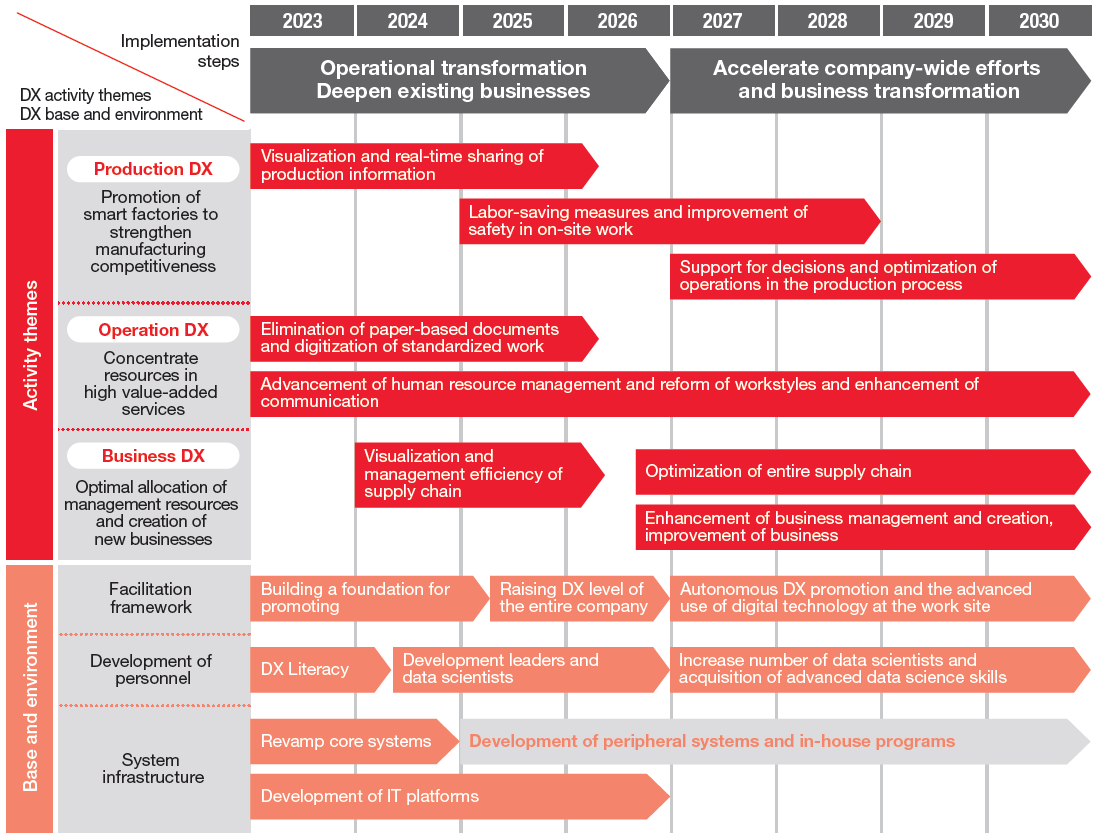

The Nippon Denko Group has classified the areas in which DX Vision will be realized into the three categories of “Production,” “Operation,” and “Business” and we will create new value in each of these areas. Production DX targets plants and strengthens manufacturing competitiveness through the introduction of smart factories. Operation DX targets back-office operations and focuses resources on high value-added services by improving operational efficiency. Business DX promotes the optimal allocation of management resources and creation of new businesses for business growth. We are also building a foundation for DX promotion by developing a system to improve productivity and quality of work, as well as a promotion system to autonomously realize DX while developing workers with specialized skills.

DX Road Map

Establishment of a DX Promotion Committee

n order to further accelerate DX activities, a DX Promotion Committee was established with the President & CEO as chairperson in January 2025. Based on the company-wide strategy, we plan to hold four meetings a year under the policy of promoting DX while maximizing return on investment and realizing overall organizational transformation. The committee’s main activities are following up on DX initiatives in line with the DX Vision and DX roadmap, managing DX strategies and investment plans, and establishing a DX culture.

DX Initiatives

Smart factory development

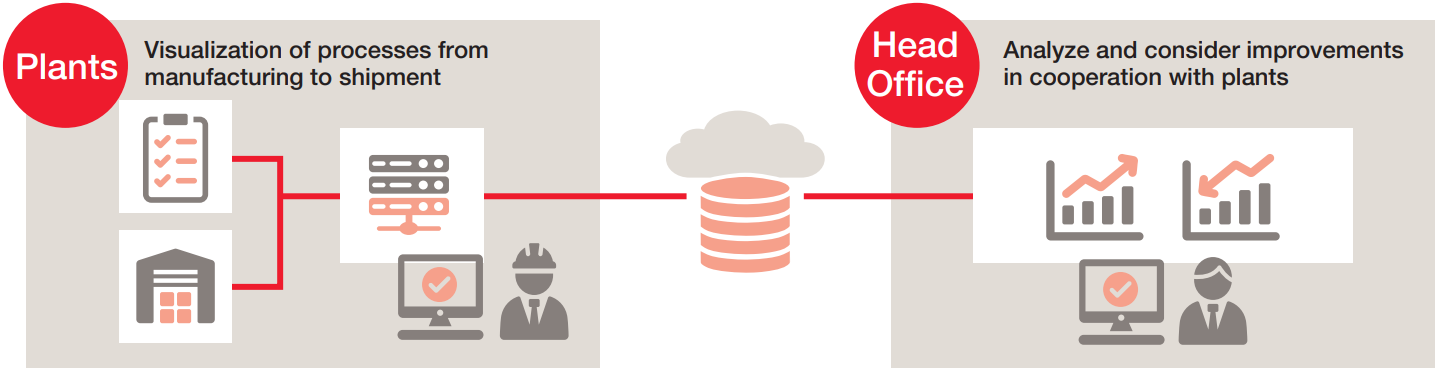

As the first stage (Phase 1) of smart factory development, we aim to improve production efficiency and operational efficiency by visualizing production information. In 2024, investments were made in the Tokushima Plant (zirconium oxide) and the Koriyama Plant (aqua solutions), and in 2025, we will consider installing the system in the Kashima Plant (incineration ash recycling) and the Tokushima Plant (ferroalloys). Specifically, we will adopt a traceability system that enables digital tracking of the entire flow from manufacturing to shipping (manufacturing, inspection, and warehousing). By building a foundation for visualizing and analysing the collected data, we aim to optimize inventory across the entire plant, improve operational efficiency, and strengthen quality control. Furthermore, by creating an environment in which the sales and manufacturing departments can share collected operational data and digital data related to equipment in real time, we aim to improve operational efficiency based on a multifaceted perspective. This information sharing will promote rapid decision-making and strengthened collaboration, and through continuous improvement activities, we will promote the creation of smart factories and strengthen competitiveness.

DX human resource development

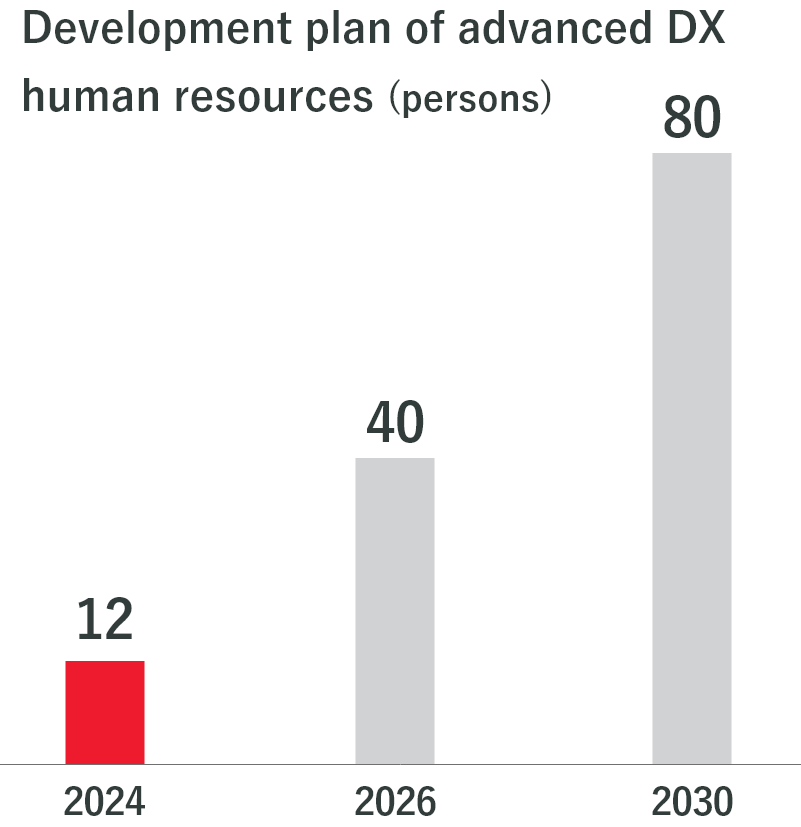

We are promoting systematic human resource development with the goal of having 80 advanced DX human resources (DX promotion leaders and data scientists) by 2030. In 2024, we selected personnel based on the previous year’s e-learning results and implemented a specialized skill acquisition program and group training. As a result of this initiative, 12 individuals are expected to be certified as advanced DX human resources after passing a qualification exam. In 2025, we will continue the same educational program and promote the development of human resources equipped with the knowledge and skills necessary to lead digital transformation.

Talent management

We are installing a new human resources system (Talent Palette) with the aim of centralizing the human resource information currently managed at each business site and conducting data-based human resource development and personnel management. This will enable us to link and visualize employees’ qualifications, work experience, education and training records, thereby clarifying development and transfer plans, and promoting career development of our employees. In addition, creating an environment that allows hierarchical access to centralized personnel information will improve operational efficiency by enabling various application procedures to be carried out in the system. The new human resources system has been operational since April 2025. We will continue to expand the scope of human resource information management as a tool for human resource strategy, linked to the management strategy.

![close[]](/en/shared/img/sp/closeBtn.png)